All of AirGreen’s products can be sold as individual modules that can be used in conjunction with existing or other HVAC components, or as standalone AirGreen Packaged Units ready for installation.

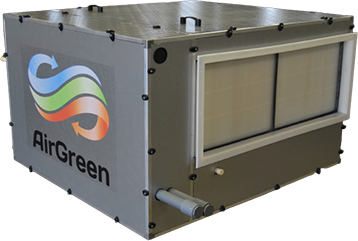

AirGreen AG2200

Standard sized system that treats up to 2,000 CFM of return or outside air and removes up to 2,200 pints per day of moisture.

Learn More

AirGreen AG3300

Larger system that conditions up to 3,000 CFM of return or outside air and removes up to 3,300 pints per day of moisture.

Learn More