The Problem

LabWare, Inc. has utilized the Oberod Estate as a training center and for hosting special events. This estate, having ten bedrooms and more than 17,000 square feet, was constructed in 1934 for a member of the DuPont family, prominent in Delaware not only for its global chemical and materials company but also for its philanthropy. The existing mechanical cooling systems were incapable of effectively managing humidity and there were many sections of this facility that were humid, and thus uncomfortable.

Back in 2017, the owner of this historic facility enthusiastically agreed to allow AirGreen to demonstrate its technology for the first time outside of an R&D facility, understanding that utilizing AirGreen’s unique ability to manage humidity might solve some of the comfort issues that existed at this unique facility. Originally the ductwork installed at the Oberod Estate was sized for heating only, as air conditioning was uncommon in the 1930’s. As a result, the air distribution system is undersized for effective air conditioning.

The AirGreen Solution

Ultimately the design approach that AirGreen selected was simple. The AirGreen equipment would improve conditions by increasing the tonnage per CFM of supply air to the estate, and it would be utilized to pre-condition the fresh (outside) supply air to 65oF or lower and dry it to 40-45% relative humidity (RH) prior to connecting with the existing HVAC equipment, ensuring that the supply air would be dry and also reducing the likelihood of any mold formation would occur within the facilities vast air duct systems. AirGreen’s founder, Andrew Mongar, built the AirGreen equipment and managed its installation into the basement of the Oberod facility.

The original air handler supplied conditioned air at a Sensible Heat Ratio (SHR) of only 0.80, resulting in either air that was uncomfortably cold using far too much energy, while doing little to remove humidity. This limitation results in the “cold and clammy” feeling occupants experience in facilities without proper humidity control.

The AirGreen equipment was to be fed by outside (fresh) air, would cool and de-humidify it, and then feed it into a large plenum feeding the existing mechanical cooling equipment. A portion of the return air from the building that matched the fresh air flowrates would be routed through AirGreen’s regenerator to re-concentrate the desiccant stream by releasing the absorbed moisture into the exhaust airstream.

This system also includes an IoT-based control and data system that allowed AirGreen to monitor and control the equipment remotely and provided a huge set of conditions and control data that allowed AirGreen to build and develop certain algorithms and control strategies used to improve comfort conditions and minimize energy consumption.

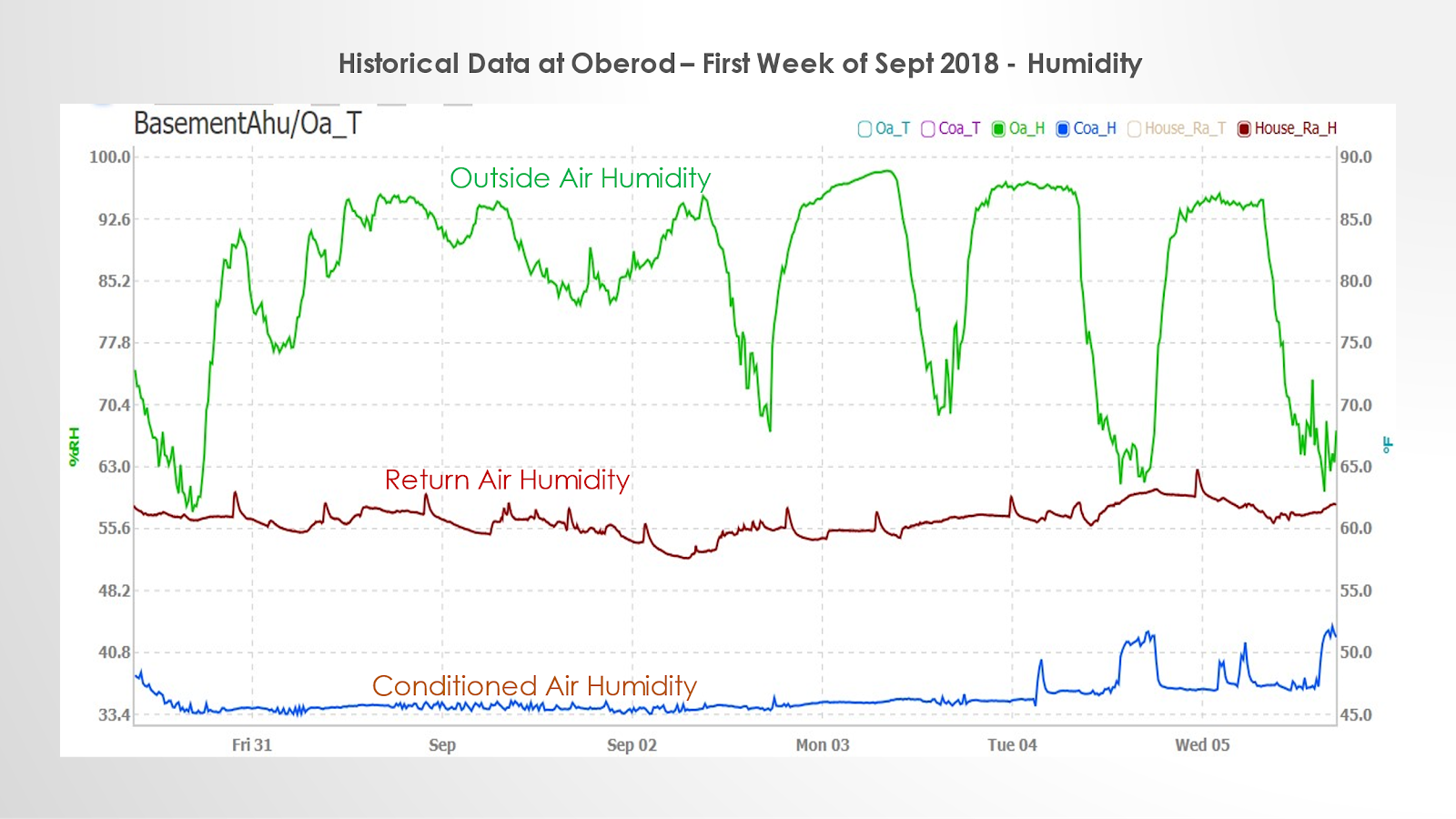

As you can see from a snapshot of data taken during hot and humid conditions in early September of 2018, the AirGreen system performed as anticipated: while outside air relative humidity (RH) conditions peaked in the mid-90 percent range, the AirGreen technology was able to strip the moisture and provide sub-40% conditioned air to the building, which resulted in building conditions at a very comfortable 55% RH.

Working With AirGreen

As our first real-world project, AirGreen needed to not only provide its innovative technology for this application, we had to integrate it into a system that was never really designed to provide comfort across a vast air distribution network. Our ability to directly and aggressively reduce humidity was the key to success in this project. Once the outside air was pre-treated and made dry and cool, comfort followed. And as a result, overcooling was generally eliminated and energy costs reduced. And airborne pathogens were scrubbed as well.

At Air Green, we love how our technology is both simple and effective. Managing humidity will be one of the primary HVAC and energy challenges going forward, and nothing strips moisture better than our approach. And low humidity = comfort = energy savings. We welcome inquiries about how the novel AirGreen can help customers solve their indoor air quality (IAQ) needs.